Retrofit Nailbase Panels

Dramatically increase energy-efficiency by adding SIP nailbase panels to existing homes.

What are Nailbase Panels?

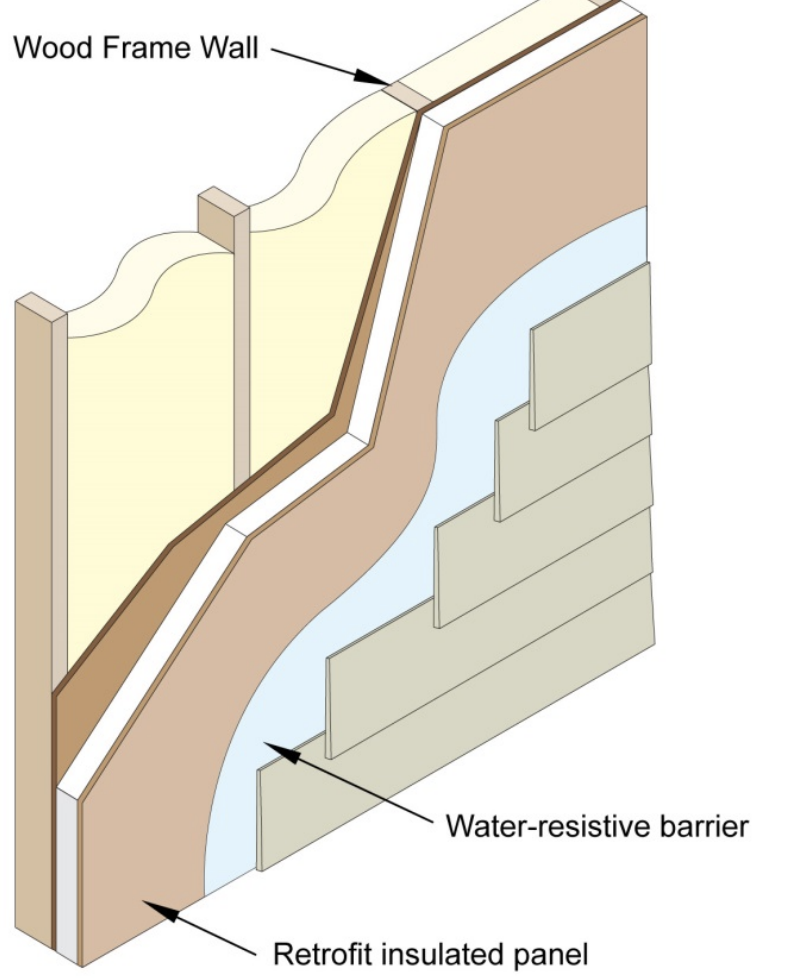

Nailbase panels, sometimes called retrofit panels, are a layer of EPS or Neopor foam added to a single sheet of OSB. Added to existing homes during roof or siding replacement, nailbase panels can dramatically increase energy efficiency. They provide both continuous exterior insulation and a solid nailing surface in a single step.

Most commonly used during roof or siding replacement, nailbase panels are similar to SIPs (structural insulated panels) but without the structural component. Rather than foam sandwiched between two layers of OSB, a nailbase panel only includes one hard side. The benefit is that they are easy to add onto existing structures but still provide a continuous layer of insulation that dramatically reduces thermal bridging.

Nailbase panel graphic provided courtesy of SIPA’s Retrofit Insulated Wall & Roof Panel Installation Guide

Most common uses for Nailbase panels

Roof Replacement

During a roof replacement, SIP nailbase panels can be added to an existing structure to dramatically increase the R-value of the roof. The new roof is then installed on top of the nailbase panels. This can significantly increase the comfort inside the home, especially in older homes with significant differences in comfort between the first and second floors. By adding insulation to the exterior of the home, finished attic space doesn’t need to be disturbed.

Siding Replacement

Nailbase panels can also be applied to exterior walls during a siding replacement project to provide continuous insulation to the exterior of the home. Depending on the specific needs of the project, nailbase panels can vary in thickness from 1.5 to 4 inches. Once the existing cladding has been removed, nail base panels are added to the existing wood frame wall. A water-resistive barrier is added on top, followed by the new siding or cladding.

Learn More About the Energy-Efficiency Benefits of Nailbase Panels

Visit the Structural Insulated Panel Association to learn more about field studies and the building science behind nailbase panels. A 2022 Insulation Industry Opportunity Study concluded that “Energy savings from insulation retrofits has the potential to reduce natural gas fossil fuel use by roughly 23 billion therms across the U.S. residential building stock, along with reducing HVAC sizing requirements and the demand on the electric grid.”

Let’s plan your next SIP project.

Still not sure if SIP panels are right for your next project or how to take the next step? Call us today for a free consultation. We’ll help you figure out if SIP panels are a good fit, what kind of panels you are likely to need and how to proceed. Then, when you are ready, we’ll provide you a full design, including detailed drawings, for your project.

Tell us about your project.

First we’ll help you decide if SIP insulated panels are right for your specific project. Then, if they are, we can talk through thickness, size and specialty panels to figure out your specific needs.

Detailed design drawings

Once you are ready to move forward with your project, we create detailed, accurate design drawings to make it as easy as possible for your builder to incorporate SIPs into your home.

Quality manufacturing

Each SIP insulated wall panel is manufactured in a factory-controlled environment to your exact specifications. Delivery is quick and easy.

Easy Installation

We provide your builder with detailed drawings and instructions to make your SIP panel installation quick and easy. In fact, SIP panel installation is typically faster than traditional construction.