SIP Panel Construction: How To Guide

Numbered panels, and easy construction make SIPs construction faster and simpler than conventional stick frame construction.

Structural Insulated Panel Construction Overview

Numbered panels make construction easier and faster.

Not only are structurally insulated panels designed to be more energy efficient for your home, they are also designed to be easier and faster to construct. Whether it is an entire home or a new roof, construction of SIP panels should move quickly for an experienced builder. In fact, SIPs can actually save on labor costs because what would typically be a multi-step process (including framing and insulating) can now be completed in a single step.

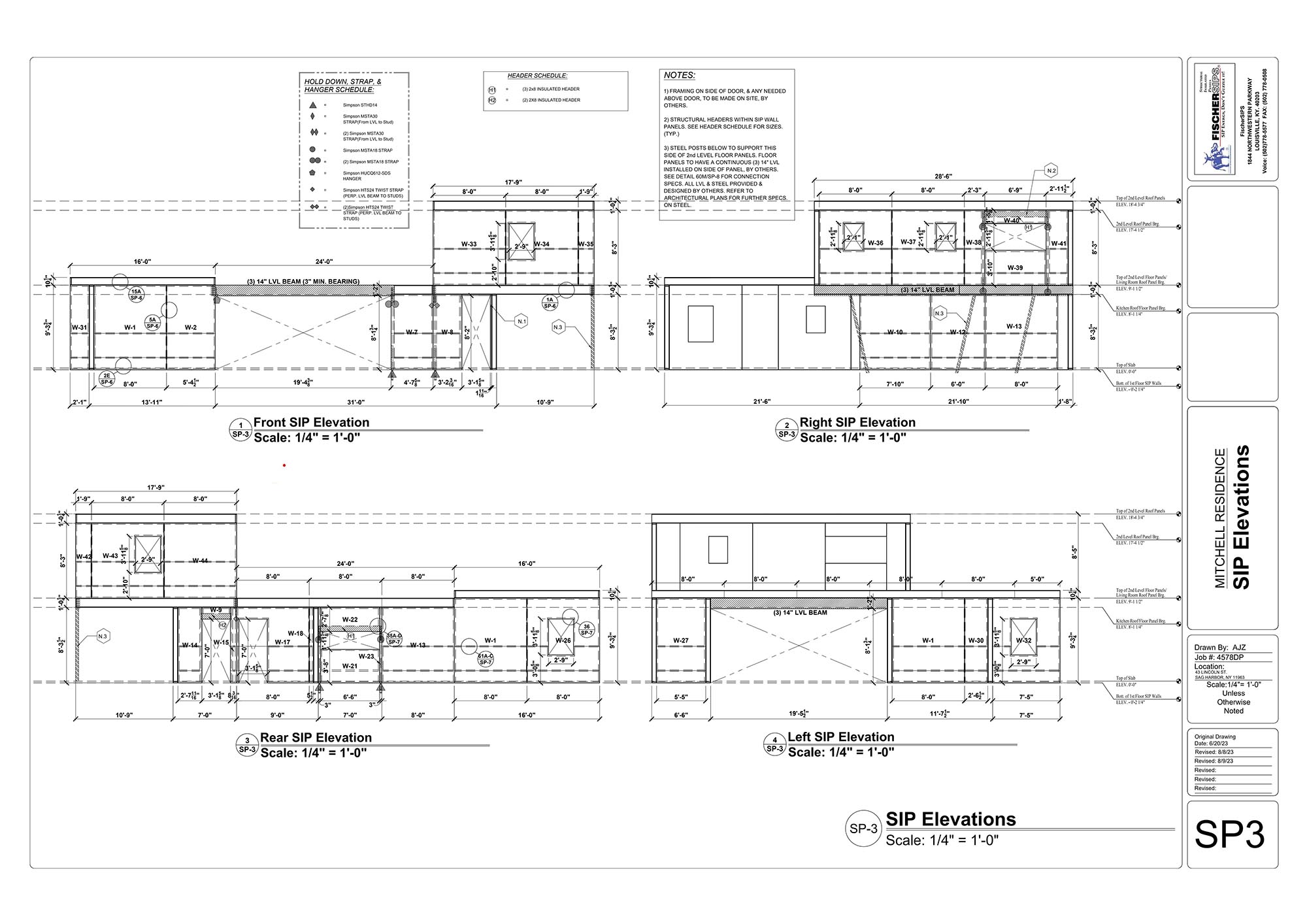

Step 1: Get a customized set of plans.

Once you have a set of house plans identified, Fischer SIPs will work with you to modify the plans to accommodate Structural Insulated Panels. Almost any plan can use SIPs and our specialized team can help you decide if you want to use SIPs on both the walls and roof, what thickness of panels you need, and how to prepare your home for using SIPs. Within a few weeks, we’ll deliver a customized set of plans that includes SIP panels for your approval.

After the plans are approved, your SIP panels will be constructed to the agreed upon specifications in our factory-controlled conditions.

Step 2: Gather your equipment for SIP panel construction

SIP panel construction requires relatively few tools. You will likely need:

- Nail gun

- 3-4′ level

- Square

- Tape measure

- Drill

- Tools to ensure panels are plumb

The most complicated equipment for most builders are actually the tools to lift the panels. When the panels arrive, a forklift with 6 foot fork extensions capable of raising 8 feet in the air is typically required to unload. Additionally, builders should consider how panels will be lifted on construction day. Large roof panels, in particular, are very heavy and require specialized equipment to lift into place.

Step 3: Construct SIP panels by following the numbers.

When you receive the kit, each panel will match your customized set of plans. Piece by piece, everything is numbered. Like an IKEA cabinet each panel size is identified in the plan with a corresponding number printed on the panels. The Panels are stacked in near order based on the size of where they go around the house. Always pick a corner to start so you have a strong foundation, and then work your way around the house, trying not to box yourself in.

SIP panel construction is completed in the following order:

Treated Plates (can be 1/2″ CDX up to Treated 2x material) are bolted or nailed into the ground, depending on whether the foundation is a slab or floor deck. Builders often choose to use standard plates available from Home Depot or Lowes so they can be set before the SIP panels arrive.

Then, the SIP bottom plate panel is attached to the bolts. The panel rests over the bottom plate on top of the treated plate. With each panel, builders will ensure the plate is square and level. Repeat this process for each new panel.

Panels are connected together. The splines are preinstalled so it is simply a matter of sliding them together and caulking. Larger joints might require expanding foam for a tight seal. You may also choose to add SIP tape after the caulk.

On average a panel can be set in 5 minutes or less. Many one-story homes in a simple shape can be constructed in half a day.

Step 4: Contact FischerSIPs with SIP construction questions.

Want to make sure you are doing it properly and need more help? FischerSIPs offers follow up consultations to builders and homeowners to make sure the process goes smoothly. Although many builders focused on energy efficiency are already familiar with the process, FischerSIPs welcomes builders that have not worked with SIPs before and will be happy to help you through the process on your SIPs construction project.

Let’s plan your next SIP project.

Still not sure if SIP panels are right for your next project or how to take the next step? Call us today for a free consultation. We’ll help you figure out if SIP panels are a good fit, what kind of panels you are likely to need and how to proceed. Then, when you are ready, we’ll provide you a full design, including detailed drawings, for your project.